Dry Ice Blasting

Soiled moulds, parts or machines are often difficult to clean. The problem sandblasting can leave spray agent such as sand or glass granulate. This often means having to clean after cleaning. This is no longer necessary with the high-performance ice blasters Diverse Cleaning use from Kärcher. After blasting, the dry ice pellets dissolve completely into carbon dioxide (CO2). The result is perfect cleanliness.

Advantages of Dry Ice Blasting

- No preparation required prior to cleaning. No need to disassemble machines for cleaning. The pellets easily reach into even the smallest nooks and crannies

- Minimal machine downtimes. Thanks to fast and effective cleaning with dry ice

- Environmentally-friendly cleaning. Without additional chemicals or spray agents

- Surfaces are not damaged

- No residues. Dry ice sublimates completely to CO2

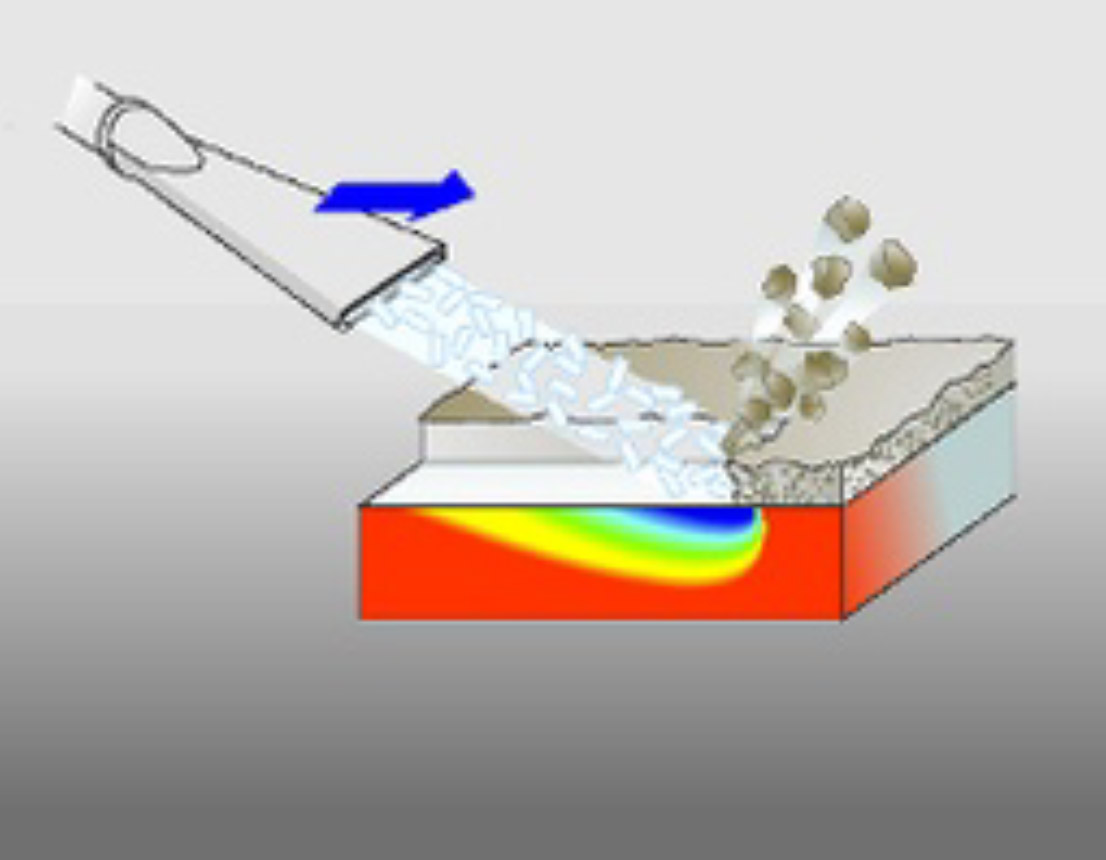

Cleanliness = Extreme Cold x Velocity

The ice blaster uses compressed air to propel the 3-mm dry ice pellets to the high velocity of over 150 m/s. The cold temperature of -79°C freezes the dirt and causes it to crack. The dry ice pellets ejected at a high speed can then remove the dirt easily. This is an especially effective method of gently removing virtually all types of dirt.

Areas of use

Steel, metal and machine construction

Deep cleaning and maintenance cleaning of production machinery, welding robots, conveyor belts and paint shops is extremely easy with Ice Blasters.

Printing plants

After dry ice blasting, all printing machines and cylinders, tools, etc., look like new.

Timber and electrical industry

Dry ice blasting is also ideal for cleaning woodworking machines, generators, turbines, control cabinets, etc.

Plastic and packaging industry

The dry ice blaster removes silicone and rubber as well as dyes, paints and other dirt from injection moulds and production lines.

Automotive industry, foundries and plastic injection moulding plants

Dry ice cleaners remove binding and parting agents from all kinds of parts and workpieces. Residues such as silicone, rubber, dyes, paints, parting agents, etc., can easily be removed from injection moulds, tools and entire production lines. Cleans perfectly without leaving residues.

Food, pharmaceutical and cosmetics industry

An ice blaster is ideal for removing coking, burnt-in deposits, encrustations, fat and starch from filling and mixing plants, production lines, handling systems as well as tanks and furnaces.

Paper industry

In the paper industry, glue, lime, dust and cellular materials are deposited in the systems. Machine downtimes and loss of quality are the result. Systems are cleaned faster with dry ice and are soon ready to use again.

Local authorities and municipalities

Graffiti and chewing gum: a problem for many cities and municipalities. This calls for a cleaning method that cleans walls and surfaces thoroughly, yet gently – like ice blasters. They remove dirt without damaging surfaces.

Marine industry

Over a period of time, the build up of anti-foul on the hull of vessels has to be removed. This can be a time consuming and very messy job but with the aid of Dry Ice blasting the process is made much easier. It is much more environmentally friendly than normal sanding and washing as there is no water run off to contaminate the surrounding area, the dry ice evaporates and the old anti foul residue is simply vacuumed up and disposed of in the relevant waste container.

Environmental compatibility of dry ice blasting

No harmful substances

No toxic or environmentally harmful chemicals or solvents are used in dry ice blasting. This means that no toxic or harmful vapours are released, and there is therefore no risk to employees from using hazardous substances that are harmful to health.

No spray agent is left over in dry ice blasting

The dislodged dirt falls to the ground and can be swept up. Only the dirt that is generated as a result of the cleaning procedure needs to be disposed of. by contrast, chemicals and solvents that are used for cleaning create hazardous waste that is difficult to dispose of.

No secondary waste

In sand-blasting, soda-blasting and water-blasting, the blasting substance itself generates hazardous waste if it has been used to remove hazardous dirt. A very large quantity of secondary waste is produced, which in some cases must be disposed of with great care and considerable cost.

Carbon dioxide production

CO2 is a by-product of other industrial processes. Carbon dioxide is produced, for example, from CO2 scrubbing in ammonia and methanol synthesis. A large proportion of the CO2 used is generated from raw carbon dioxide produced as a waste gas in the chemical processing of crude oil and gas. Carbon dioxide is also produced by combustion processes in power stations and in fermentation processes.

That’s why CO2 no longer needs to be specially produced in industrialised countries, and burning fossil fuels to generate CO2 is now a thing of the past.

We use all of the relevant safety wear and take appropriate precautions when using the equipment including, hearing protection as noise levels can rise above 85dB(A). Gloves to prevent frostbite, Safety goggles. Breathing apparatus if required as a carbon monoxide detector to alert the team member as soon as critical concentration is reached.